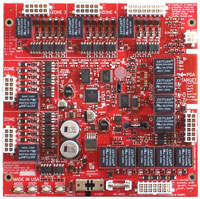

Atlanta Series Geothermal HVAC Control Board

Hardware Highlights

P/N

236-802

Connector Organization

The eight connectors on Atlanta series control boards

are grouped intelligently. Careful

planning and forethought was used to group connectors by how the wire harnesses

will be run and connect to various systems in the heat pump. Wherever needed,

24 VAC and/or common outputs are provided on individual pins and grouped with

their associated harness. In other words, the supply and return wires from one

harness do not have to run to a second connector or to a separate transformer

bus for power or returns. The connectors are grouped like this:

are grouped intelligently. Careful

planning and forethought was used to group connectors by how the wire harnesses

will be run and connect to various systems in the heat pump. Wherever needed,

24 VAC and/or common outputs are provided on individual pins and grouped with

their associated harness. In other words, the supply and return wires from one

harness do not have to run to a second connector or to a separate transformer

bus for power or returns. The connectors are grouped like this:

- Four independent zone connectors

- Compressors & pumps connector

- Fans & emergency connector

- Sensor connector

- Expansion connector (return to summary page)

Damper Control

The four damper control relays on the Atlanta series control board supply 24 VAC. Damper outputs are included in the four zone connectors. Each zone based damper control output can drive NO and/or NC dampers. (return to summary page)

Stages and Compressors

Atlanta series control boards are capable of controlling heat pumps of 1, 2, or 3 stages made up of 1 or 2 compressors. Compressors can be single or two speed types, and there is support for 2 single stage compressors. (return to summary page)

System Status LEDs

All inputs and outputs on Atlanta series control boards have LED indicators that use "positive logic". This means that when an input or output is powered, the LED is illuminated, and when an input or output is off, the LED is off. System status LEDs for Atlanta series control boards are green. There are LEDs for each of the following:

Inputs

|

Outputs

|

Diagnostic LEDs

Diagnostic LEDs are provided to aid the installer, technicians, and even the user of system problems. Diagnostic LEDs are red. Most of them flash while issues are active, and then stay on when the problem has been resolved to give the person diagnosing the problem a visual recording of what problems have occurred. Pressing the reset button on the keyboard turns off diagnostic LEDs on Atlanta series control boards. There are diagnostic LEDs for each of the following:

- Service Required

- Loop heat exchanger freeze prevention (FreezeCop TM) was activated

- Freon high over pressure

- Freon medium over pressure (does not latch)

- Freon low under pressure

- System lock out

- Test mode entered, thermostat inputs ignored (does not latch) (return to summary page)

Dual Microcontrollers

To help prevent damage in the event of failure on the motherboard, the Atlanta series control board uses two microcontrollers. The primary processor handles all inputs, high level functions, and HVAC processes. The secondary processor handles some low level functions, power supply sequencing, clock operations, and monitors the primary processor. If the primary processor locks up or fails to boot, the secondary processor shuts down the outputs on the control board and attempts to restart the primary processor. In that case, outputs on the control board would be inactive until the primary processor becomes active again. (return to summary page)

Keyboard

Atlanta series control boards have a basic keyboard on the lower left corner. Its purpose is to provide a rudimentary interface when a PDA is not available. The keys allow the user to change the run mode, step through test sequences, toggle the freon reversing valve, search for new sensors, and performing soft resets on the primary processor. (return to summary page)

Optically Isolated Inputs

Thermostat wires make very long antennas and can induce high voltages on heat pump control boards. To meet Georgia Controls' high standards for reliability, Atlanta series control boards utilize Transient Voltage Supressors and optically isolated inputs (and in some cases outputs) to protect the motherboard against high voltages from electrostatic discharge and near-strike lightning. For the OEM this level of protection means reduced warranty service calls and claims, thus reflecting well on the OEM's heat pump. For the customer, it means a more robust, reliable, survivable control board that should give many years of quality service without down time. (return to summary page)

Fan Drive Choices

For Atlanta series control boards, Georgia controls includes support for multiple fan drive types. These types cover the most widely used fan motor types used by the industry:

- Single speed

- Multispeed motors with exclusive inputs (F1 only, F2 only, F3 only) for each speed

- Multispeed motors with cumulative inputs (F1 only, F1 + F2, F1 + F2 + F3) for each speed

- Variable speed motor output (G + PWM) for GE and compatible ICM2+ Advanced Motor Control style fans

For OEMs, Georgia controls can provide conversions to other, less used fan drives. E-mail or call for more information. (return to summary page)

Auxiliary Function Relays

The Atlanta controllers have one to four auxiliary outputs, depending on the heat pump configuration. As a minimum, one single auxiliary relay ("Aux") is available to perform extra functions. Control boards connected to variable speed fan drives do not use the three F relays. In this case, the unused F relays are available as auxiliary relays as well. This allows OEMs and installers who use the Atlanta series control boards to select any of the following closure outputs to drive external contactors, indicators, etc.:

|

|

Additionally, the "Aux" relay can be selected to be used for a second water pump drive for use in systems with two domestic hot water systems. Atlanta series control boards can supply two independent hot water tanks/systems in addition to forced air.

For OEMs, Georgia controls can add other auxiliary relay functions. E-mail or call for more information. (return to summary page)

Condensate Input

Condensate Input

![]() Atlanta series control boards have a micro current condensate sensing system

called DripCop. With this, OEMs can put a simple two conductor connector at

their desired "full" level of the condensate pan and sense when condensate

backs up into the pan with no moving parts. When the DripCop system

detects a condensate backup, the Atlanta control board will shut down the

compressors immediately and not allow them to come back on until the condensate

problem has been addressed.

(return to summary page)

Atlanta series control boards have a micro current condensate sensing system

called DripCop. With this, OEMs can put a simple two conductor connector at

their desired "full" level of the condensate pan and sense when condensate

backs up into the pan with no moving parts. When the DripCop system

detects a condensate backup, the Atlanta control board will shut down the

compressors immediately and not allow them to come back on until the condensate

problem has been addressed.

(return to summary page)